RP HP UHP 650mm/ 600mm/550mm Graphite Electrode

Basic Info

| Type | Graphite Electrodes |

| Composition | Petroleum Coke and Pitch Coke |

| Carbon Content | High-Carbon |

| Grade | Industrial Grade |

| Forming Way | Extruded Graphite |

| Crystal Morphology | Graphiting |

| Specifications | UHP HP RP |

| Actual Dia | 200-700mm |

| Actual Length | 1600-2800mm |

| Transport Package | Wooden Package |

| Specification | As per your request |

| Trademark | TTWY |

| Origin | China |

| HS Code | 8545110000 |

| Production Capacity | 1500mt/Month |

Product Description

Graphite Electrodes are a high-temperature resistant graphite conductive refractory material used in the metallurgical industry. Graphite Electrodes are made of petroleum coke, bituminous coke as aggregates, coal tar pitch as binders, after raw material calcination, crushing and milling, batching, kneading, moulding, roasting, impregnation, graphitization and machining, which are also known as artificial graphite electrodes in order to distinguish from natural graphite electrodes made of natural graphite.

> Be careful when transporting and pilling electrodes with a forklift and avoid a collision. One layer of goods at a time; notice the balance and alignment and avoid falling or breakage.

> When loading and unloading with a forklift, wire rope must be used and steel wrapping tape cannot be employed directly to fetch electrodes.

> Electrode should be stored in a clean and dry place. When pilling up outdoors, it should be covered with rain-proof tarpaulin and the number of piling layers ought not to exceed four.

> When using electrodes, special tools should be employed to cut the steel wrapping tape, and crane should not be adopted to avoid bursting.

> Steel-wire ball, metallic brush or emery cloth is not allowed for cleaning the electrode thread, but compressed air free of oil and water is available.

> Use revolved resilient hanger and put soft truss pad under the electrode joint to avoid breakage of the thread.

> Lift the electrode to the furnace by using a hoister with resilient hangers, and find out the centre and move slowly downwards, screw and tighten with a hoop.

> If the two poles of the two electrodes are untouched or touched in overpressure, this may cause a bad effect.

> In order to avoid electrode breakage put the large materials in the lower part and small materials in the upper part.

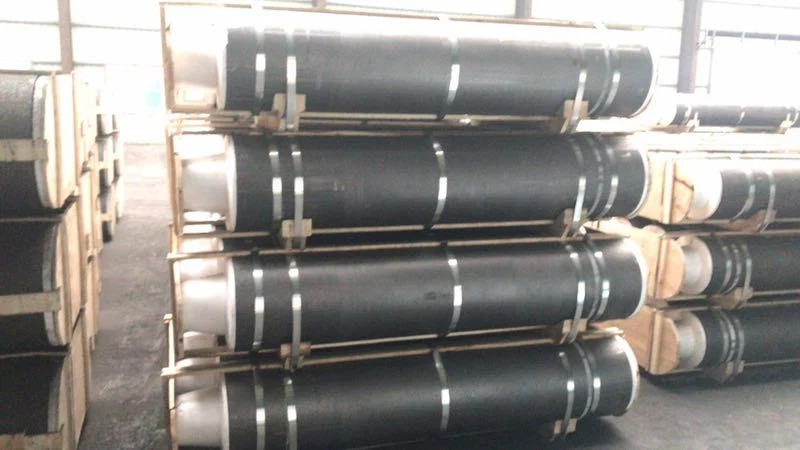

Detailed Photos

Product Parameters

| RP | HP | UHP |

| Electrode: Bulk Density≥ 1.56g/cm3 Specific Resistivity≤ 8.5μm Bending Strength≥ 10.0MPa Elastic Modulus≤ 9.3GPa Thermal Expansion Coefficient≤ 2.7x10 -6/°C Ash≤ 0.5% Nipple: Bulk Density≥ 1.68g/cm3 Specific Resistivity≤ 7.0μm Bending Strength≥ 14.0MPa Elastic Modulus≤ 13.7GPa Thermal Expansion Coefficient≤ 2.5 x10 -6/°C Ash≤ 0.5% | Electrode: Bulk Density≥ 1.65g/cm3 Specific Resistivity≤ 6.5μm Bending Strength≥ 12.0MPa Elastic Modulus≤ 10.0GPa Thermal Expansion Coefficient≤ 2.2x10 -6/°C Ash≤ 0.3% Nipple: Bulk Density≥ 1.74g/cm3 Specific Resistivity≤ 5.5μm Bending Strength≥ 16.0MPa Elastic Modulus≤ 14.0GPa Thermal Expansion Coefficient≤ 2.0 x10 -6/°C Ash≤ 0.3% | Electrode: Bulk Density≥ 1.68g/cm3 Specific Resistivity≤ 5.8μm Bending Strength≥ 16.0MPa Elastic Modulus≤ 14.0GPa Thermal Expansion Coefficient≤ 1.9x10 -6/°C Ash≤ 0.2% Nipple: Bulk Density≥ 1.76g/cm3 Specific Resistivity≤ 4.5μm Bending Strength≥ 18.0MPa Elastic Modulus≤ 16.0GPa Thermal Expansion Coefficient≤ 1.4 x10 -6/°C Ash≤ 0.2% |

| Actual diameters | Actual lengths | ||||||

| Mm | Mm | MAX | MIN | Rough spot | Length | Tolerance | Shot Ruler size |

| 200 | 8 | 204 | 201 | 198 | 1600 | ±100 | -275 |

| 250 | 10 | 256 | 252 | 248 | 1600 1800 | ||

| 300 | 12 | 307 | 303 | 299 | |||

| 350 | 14 | 357 | 353 | 347 | |||

| 400 | 16 | 409 | 404 | 400 | 1600 1800 2000 | ||

| 450 | 18 | 460 | 455 | 451 | |||

| 500 | 20 | 511 | 506 | 502 | |||

| 600 | 24 | 613 | 607 | 604 | |||

| 780 | 31.2 | 782 | 776 | 774 | 2000 2200 2400 | ±100 | -400 |

| 800 | 32 | 802 | 796 | 794 | |||

| 870 | 34.8 | 872 | 866 | 862 | |||

| 900 | 36 | 902 | 896 | 892 | |||

| 920 | 36.8 | 922 | 916 | 912 | |||

| 960 | 38.4 | 962 | 956 | 952 | |||

| 1020 | 40.8 | 1022 | 1016 | 1012 | 2200 2600 2800 | ||

| 1060 | 42.4 | 1062 | 1056 | 1052 | |||

| 1100 | 44 | 1102 | 1092 | 1092 | |||

| 1146 | 45.8 | 1148 | 1140 | 1138 | |||

| 1197 | 47.9 | 1199 | 1191 | 1189 | |||

| 1250 | 50 | 1252 | 1244 | 1242 | |||

| 1272 | 50.9 | 1274 | 1266 | 1264 | |||

| 1305 | 54.4 | 1307 | 1299 | 1297 | |||

| 1321 | 52.8 | 1323 | 1315 | 1313 | |||

| 1400 | 56 | 1402 | 1394 | 1392 | |||

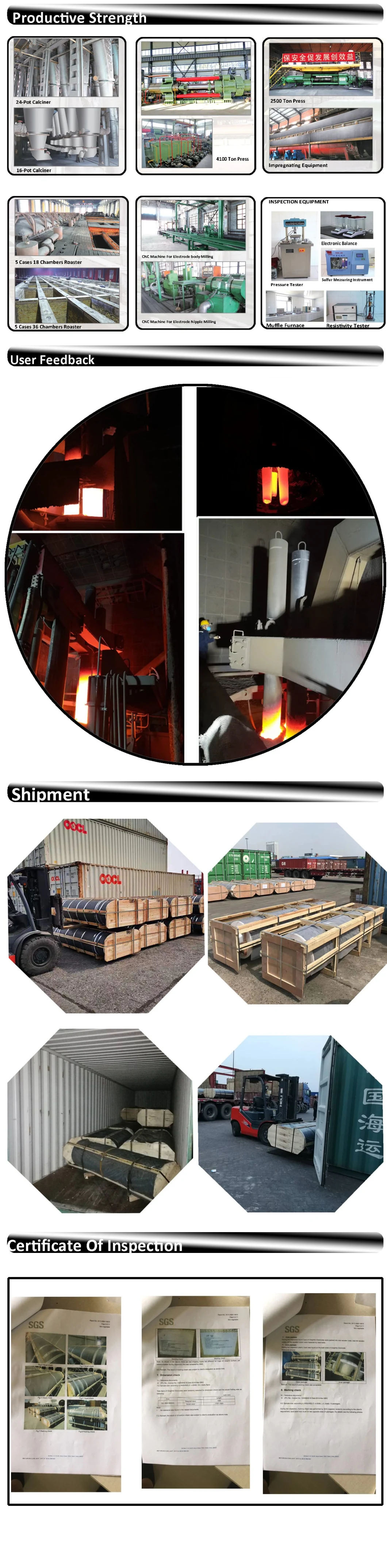

With high quality,reasonable price and attentive service the products produced by TTWY have wined trust from clients at home and aboard.FAQ

Q1: Where can I get product and price information?

A1: Send us inquiry email, we will contact with you, once we receive your email, or contact me on WhatsApp, Linkedin, Skype and WeChat.

Q2: What's the payment terms?

A2: 30% of the payment should be paid in advance, and the balance should be paid on seeing the scan copy of BL; L/C is also welcomed.

Q3: How to deliver the goods?

A3: We deliver the goods by truck to the port, or loading in containers in our factory.

Q4: What's the minimum order quantity?

A4: 18-20tons, one 20 fcl.

Q5: What's the delivery time?

A5: 2-3 weeks after got the deposit.