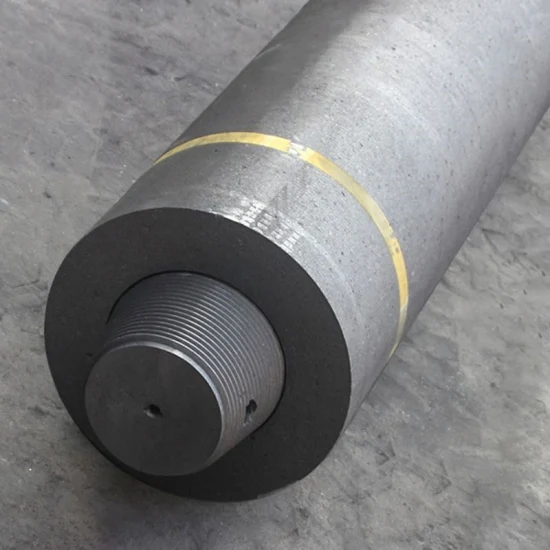

Flawless 350mm HP Graphite Electrode

Basic Info

| Model NO. | HP 350mm |

| Type | Graphite Electrodes |

| Composition | Needle Coke |

| Carbon Content | High-Carbon |

| Grade | HP |

| Forming Way | Extruded Graphite |

| Crystal Morphology | Flake Graphite |

| Graphite Electrode | HP 350mm |

| Electrode | HP 350mm |

| Graphite | HP 350mm |

| Carbon | HP 350mm |

| Transport Package | Plywood Packing, Seaworthy Packing |

| Specification | 300-400/450-500/550-700 |

| Trademark | CALGON/KFCC/FDRG |

| Origin | China |

| HS Code | 8545110000 |

| Production Capacity | 20000000tons Years |

Product Description

Product Description

Consumption of graphite electrode and outer circular surface in electric furnace

The arc produced by the graphite electrode in the electric arc furnace can be divided into long, medium and short arc, while the melting charge and temperature rise depend on the arc power. The arc length is proportional to the secondary voltage and inversely proportional to the secondary current and the heating rate. In order to increase the smelting speed and shorten the smelting time greatly, the high chemical energy operation of forced oxygen blowing is adopted, which puts forward higher requirements on the oxidation resistance and thermal shock resistance of graphite electrode. The end consumption of graphite electrodes in smelting includes sublimation due to high arc temperature and chemical reactions due to contact with molten steel and steel slag. The oxidation loss of graphite electrode accounts for about 2/3 of the total consumption, and the oxidation loss is the product of unit oxidation rate and area, and is proportional to the time. The longer the heating time in smelting, the greater the consumption, so it is very necessary to install the water-cooled spray system on the electrode of electric arc furnace. In normal smelling, the carbon content of graphite electrode into molten steel is about 0.01%, and the consumption switch at the end is not conical tip.

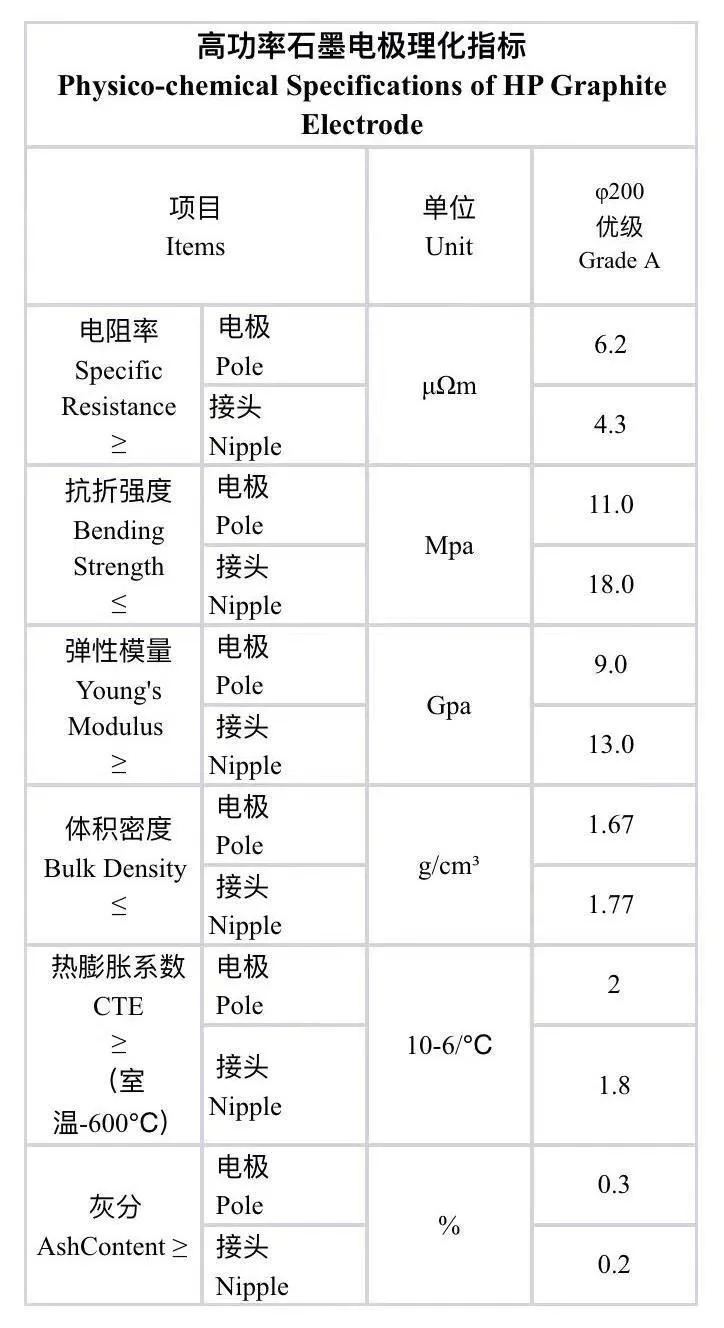

Product SpecificationApplicable Nipple informationPackageTransport & Export

Our after sales service

Calgon Carbon has an experienced and highly skilled service team, which always insisting on the service concept of "honest service and perfection", continuously deepening marketing services, extending service contents for the whole process of, pre-sales, in-sales, and after-sales throughout the entire marketing process, which providing the customer with technical positioning, guidance, and full tracking service of steel making testing. Calgon Carbon promises to reach the worksite within72 hours to analyze and solve the problem with the user for the anomalies and problems of electrodes using.

Hot Tags: 350mm hp graphite electrode, suppliers, factory, price, quotation, made in China, graphite electrode for eaf, graphite electrode uhp, , graphite electrode for arc furnaces, kfcc graphite electrode, super high power graphite electrode